|

|

24 August 2020, 08:40

24 August 2020, 08:40

|

#81

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

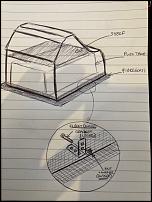

Thanks! Using both 100mm and 150mm sounds a good idea! Glassing from the inside isnít really possible as I will fit the fuel tank down inside the console and there is a shelf I am putting inside the console. One possibility might be to pre fit a couple of SS brackets inside to the floor and pre insert bolts then try to find a way of feeding those bolts through pre drilled holes as per my sketch below but Iím not entirely sure that would be possible.

I think I should have it done by about early to mid October. Weather permitting Iíll still go out then even though the warm weather has gone

__________________

|

|

|

24 August 2020, 08:57

24 August 2020, 08:57

|

#82

|

|

RIBnet supporter

Country: UK - England

Town: Brixham

Boat name: Jazz

Make: XS

Length: 6m +

Engine: Suzuki

Join Date: Aug 2018

Posts: 195

|

If you pre wet the strips of mat your going to use to bond the console to the deck on a board first, then lay them in place and roll out any air you can get a much neater finish.

The trick is to not roll the edges to death. Because you've pre wet them there's plenty of resin on the bonding area so a lightish roll to get them into the deck console join and to make sure there's contact over the whole of the strip should be sufficient.

__________________

|

|

|

24 August 2020, 09:04

24 August 2020, 09:04

|

#83

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by 36valley

If you pre wet the strips of mat your going to use to bond the console to the deck on a board first, then lay them in place and roll out any air you can get a much neater finish.

The trick is to not roll the edges to death. Because you've pre wet them there's plenty of resin on the bonding area so a lightish roll to get them into the deck console join and to make sure there's contact over the whole of the strip should be sufficient.

|

Thank you, very useful!

So lay the strips on a separate board, apply the resin until wet through with resin, lift up strip and apply to join and gently roll it to get good contact. Sounds like a good system! How many strip layers would you suggest? Also would you suggest like Ribtecer using the 100mm first, let dry then 150mm over the top? Perhaps two layers of each? With that would you suggest I donít need any inside fitting - which I canít really work out how to do to be honest, I think only exterior fitting is possible.

Iím also thinking it might be an idea to strengthen with more fibreglass the very bottom of the console on the inside before fitting.

__________________

|

|

|

24 August 2020, 09:07

24 August 2020, 09:07

|

#84

|

|

Member

Country: UK - England

Town: Retford

Boat name: Spy-sea-one

Make: Excel 435

Length: 4m +

Engine: Suzuki Outboard/25/4

Join Date: Oct 2011

Posts: 7,454

|

this is what i would use, you can buy sandwich tape which is with cloth, a quick call to these will help i found them very helpful.

https://www.ecfibreglasssupplies.co....e-200g-x-100mm

__________________

|

|

|

24 August 2020, 09:09

24 August 2020, 09:09

|

#85

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by jeffstevens763@g

|

Thanks Jeff

__________________

|

|

|

24 August 2020, 09:55

24 August 2020, 09:55

|

#86

|

|

RIBnet supporter

Country: UK - England

Town: Brixham

Boat name: Jazz

Make: XS

Length: 6m +

Engine: Suzuki

Join Date: Aug 2018

Posts: 195

|

Quote:

Originally Posted by xpertski

Thank you, very useful!

So lay the strips on a separate board, apply the resin until wet through with resin, lift up strip and apply to join and gently roll it to get good contact. Sounds like a good system! How many strip layers would you suggest? Also would you suggest like Ribtecer using the 100mm first, let dry then 150mm over the top? Perhaps two layers of each? With that would you suggest I donít need any inside fitting - which I canít really work out how to do to be honest, I think only exterior fitting is possible.

Iím also thinking it might be an idea to strengthen with more fibreglass the very bottom of the console on the inside before fitting.

|

Work as quick as you can when weting out the strips and laying them in place as they don't use much binding agent on mat these days and the resin breaks it down very quickly. 40 years ago you could wet out the strips and have plenty of time to lay them in place without them falling apart in your hands, not any more .

Personally I would use 3 layers of 450 csm about 100mms wide layed in one go and be confident that would hold everything in place. You won't get as good a bond if you allow each layer to dry first.

What you need to make sure is that you've keyed and cleaned well the surfaces on the floor and console that you've laying the wet mat onto.

I've been out of the fibreglass business for more than 15 years now so my way of doing things will be a little old school. More up to date guys may have better/modern ways of going about things.

__________________

|

|

|

24 August 2020, 09:59

24 August 2020, 09:59

|

#87

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by 36valley

Work as quick as you can when weting out the strips and laying them in place as they don't use much binding agent on mat these days and the resin breaks it down very quickly. 40 years ago you could wet out the strips and have plenty of time to lay them in place without them falling apart in your hands, not any more .

Personally I would use 3 layers of 450 csm about 100mms wide layed in one go and be confident that would hold everything in place. You won't get as good a bond if you allow each layer to dry first.

What you need to make sure is that you've keyed and cleaned well the surfaces on the floor and console that you've laying the wet mat onto.

I've been out of the fibreglass business for more than 15 years now so my way of doing things will be a little old school. More up to date guys may have better/modern ways of going about things.

|

Thank you! Thatís really helpful! The tape is 200g so I guess just double up to they to the 400gsm ie 6 layers? Or technically 7

__________________

|

|

|

24 August 2020, 15:40

24 August 2020, 15:40

|

#88

|

|

RIBnet supporter

Country: UK - England

Town: Brixham

Boat name: Jazz

Make: XS

Length: 6m +

Engine: Suzuki

Join Date: Aug 2018

Posts: 195

|

Quote:

Originally Posted by xpertski

Thank you! Thatís really helpful! The tape is 200g so I guess just double up to they to the 400gsm ie 6 layers? Or technically 7

|

I may be misunderstanding what your planing to do, if so I apologise, but I wouldn't use cloth tape on its own. It won't bond anywhere near as well as chopped strand mat to an existing surface.

If you really want to go that route try a piece on a scrap bit of fiberglass first. Let it cure properly for a few days and then see how easy it will peel away from that piece to make sure your happy with the adhesion.

Cloth tape works best when sandwiched between layers of chopped strand mat or when rolled on to a wet laminate and cured at the same time as the rest of that lay up. It then gives you the strength of a much heavier chopped mat lay up with out the bulk and weight.

Many, many years ago I used to bond race boat hulls and decks together with glass roving (A much heavier version of the tape your looking at) sandwiched between two layers of 600gsm (2oz in those days!) . It was done in the same way as I'm suggesting you wet out your strips, only difference being you won't be laying on your back with a load of wet glassfibre above your face in the bow of a boat, fast being overcome by Styrene fumes. Back in the days when a rag wrapped around your face was an acceptable nod to health and safety

__________________

|

|

|

24 August 2020, 17:25

24 August 2020, 17:25

|

#89

|

|

Member

Country: UK - England

Town: Waterlooville

Boat name: Tickler

Make: Halmatic P22

Length: 6m +

Engine: Inboard Diesel 240HP

MMSI: 235115642

Join Date: Sep 2015

Posts: 1,777

|

I think I'd suggest laminating a 100mm wide strip of CSM on to the deck in way of the footprint of the console. It will give you a better surface to bond to. One other option would be to 'bond' the console down and then you can run round the edge with a fillet to reduce the difficulty of trying to consolidate the GRP into a 90 degree corner.

ECF sell consolidating rollers for getting into corners etc.

__________________

|

|

|

24 August 2020, 17:46

24 August 2020, 17:46

|

#90

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by 36valley

I may be misunderstanding what your planing to do, if so I apologise, but I wouldn't use cloth tape on its own. It won't bond anywhere near as well as chopped strand mat to an existing surface.

If you really want to go that route try a piece on a scrap bit of fiberglass first. Let it cure properly for a few days and then see how easy it will peel away from that piece to make sure your happy with the adhesion.

Cloth tape works best when sandwiched between layers of chopped strand mat or when rolled on to a wet laminate and cured at the same time as the rest of that lay up. It then gives you the strength of a much heavier chopped mat lay up with out the bulk and weight.

Many, many years ago I used to bond race boat hulls and decks together with glass roving (A much heavier version of the tape your looking at) sandwiched between two layers of 600gsm (2oz in those days!) . It was done in the same way as I'm suggesting you wet out your strips, only difference being you won't be laying on your back with a load of wet glassfibre above your face in the bow of a boat, fast being overcome by Styrene fumes. Back in the days when a rag wrapped around your face was an acceptable nod to health and safety

|

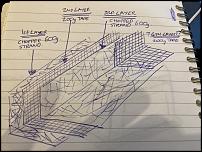

Thanks! You understood me correct so thanks for the guidance not to only use cloth tape. So if I understand correct the layers would be 600g chopped straw first, then glass cloth tape (200g), then 600g chopped straw giving the three layers. Could you the finish with tape to get a neater finish as a fourth layer? See below.... (thanks again!)

__________________

|

|

|

24 August 2020, 18:09

24 August 2020, 18:09

|

#91

|

|

Member

Country: UK - England

Town: Retford

Boat name: Spy-sea-one

Make: Excel 435

Length: 4m +

Engine: Suzuki Outboard/25/4

Join Date: Oct 2011

Posts: 7,454

|

On you tube there's an XS rib build showing all you need mate

__________________

|

|

|

24 August 2020, 18:25

24 August 2020, 18:25

|

#92

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by GuyC

I think I'd suggest laminating a 100mm wide strip of CSM on to the deck in way of the footprint of the console. It will give you a better surface to bond to. One other option would be to 'bond' the console down and then you can run round the edge with a fillet to reduce the difficulty of trying to consolidate the GRP into a 90 degree corner.

ECF sell consolidating rollers for getting into corners etc.

|

Thanks Guy! That gives me an added idea ... create an internal facing flange which I can then either bond onto 100mm GSM for an ultra strong finish or use sikaflex on the underside of the internal flange, then fibreglass the console down on the outside bottom edge as discussed here. Much stronger [emoji106]

__________________

|

|

|

24 August 2020, 18:30

24 August 2020, 18:30

|

#93

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by jeffstevens763@g

On you tube there's an XS rib build showing all you need mate

|

Thanks Jeff - watching it now, useful!

__________________

|

|

|

24 August 2020, 18:48

24 August 2020, 18:48

|

#94

|

|

RIBnet supporter

Country: UK - England

Town: Brixham

Boat name: Jazz

Make: XS

Length: 6m +

Engine: Suzuki

Join Date: Aug 2018

Posts: 195

|

Quote:

Originally Posted by xpertski

Thanks! You understood me correct so thanks for the guidance not to only use cloth tape. So if I understand correct the layers would be 600g chopped straw first, then glass cloth tape (200g), then 600g chopped straw giving the three layers. Could you the finish with tape to get a neater finish as a fourth layer? See below.... (thanks again!)

Attachment 134737 |

That would work.

I would suggest you practice on a similar shape, a block of wood on a piece ply maybe, just to make sure you get the look your after. I still think you will struggle to get the corners neat unless they have a large radius to them. But I'm very often wrong and hope I am this time.

As long as you've got a reasonable weight of glassfibre it will be strong enough so long as you get a good key to the deck surface.

__________________

|

|

|

24 August 2020, 21:24

24 August 2020, 21:24

|

#95

|

|

Member

Country: UK - Channel Islands

Town: Jersey

Boat name: Jazcabel

Make: Ballistic

Length: 7m +

Engine: Petrol 150

Join Date: May 2017

Posts: 354

|

Quote:

Originally Posted by xpertski

Auto bilge I meant [emoji23] donít mean to send this thread southwards!

Thanks for your replies - Iíll put an extra set of cables through for the bilge

|

Iím on a swinging mooring and have 2 batteries connected via a blue sea acr and isolator switch. My two bilge pumps have auto and manual applications. Manual via isolator up to console and built in auto float bypassing isolator directly to leisure battery.

Works A treat aNd will self bail only when float is activated rather than those that self check every few minutes.

__________________

|

|

|

15 September 2020, 12:12

15 September 2020, 12:12

|

#96

|

|

Member

Country: UK - England

Boat name: Jetset

Make: Demon Ribs

Length: 6m +

Engine: Mercury 225 Opti

Join Date: Mar 2016

Posts: 87

|

Quote:

Originally Posted by xpertski

Thanks, yeah will keep updating [emoji106]

Just about to book it in for flexi teak as well. Jobs on the list while I refit include re polishing all the stainless, will hopefully look pretty new and fresh when Iím finished [emoji846]

|

I'll be interested in the results and install for your Flexi teak. Its an upgrade I want on my rib at some point in future.

__________________

|

|

|

15 September 2020, 12:27

15 September 2020, 12:27

|

#97

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by Bjohnson

I'll be interested in the results and install for your Flexi teak. Its an upgrade I want on my rib at some point in future.

|

Absolutely Iíll post the outcome in the coming weeks. I have all of next week off work to work on the boat after which I should be ready to measure and order the flexi teak (deposit paid but not ordered the material to be made yet). Getting closer!

__________________

|

|

|

23 September 2020, 22:11

23 September 2020, 22:11

|

#98

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Sorry for the basic question - but would you use polyester resin or epoxy to fibreglass a console to the deck? I was going to use polyester but some websites say for anything structural or binding epoxy should be used (as itís stronger). Presume I can still use with 900gsm chopped strand either side of woven roving glass tape?

__________________

|

|

|

23 September 2020, 22:34

23 September 2020, 22:34

|

#99

|

|

RIBnet supporter

Country: UK - England

Town: Brixham

Boat name: Jazz

Make: XS

Length: 6m +

Engine: Suzuki

Join Date: Aug 2018

Posts: 195

|

I would use polyester if it was me. I doubt there's many rib builders using epoxy in anything other than lightweight hitec boats.

Definitely none in my XS.

__________________

|

|

|

23 September 2020, 22:40

23 September 2020, 22:40

|

#100

|

|

Member

Country: UK - England

Town: Surrey

Boat name: ocean pro 6.3

Make: Humber

Length: 6m +

Engine: 140hp suzuki

Join Date: Feb 2004

Posts: 824

|

Quote:

Originally Posted by 36valley

I would use polyester if it was me. I doubt there's many rib builders using epoxy in anything other than lightweight hitec boats.

Definitely none in my XS.

|

Thank you!

__________________

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|