|

|

15 June 2018, 19:54

15 June 2018, 19:54

|

#1

|

|

Member

Country: UK - England

Town: Portsmouth Area

Boat name: Busy Bee

Make: Ribcraft

Length: 5m +

Engine: Suzuki

Join Date: Jan 2012

Posts: 128

|

Grease or not

On your boat trailer what grease do you put on the wheel studs or bolts, marine grease, copper grease or something else?

__________________

|

|

|

15 June 2018, 20:20

15 June 2018, 20:20

|

#2

|

|

Member

Country: UK - England

Town: Lincoln

Boat name: Zoom

Make: Zodiac

Length: 3m +

Engine: Mariner 10

Join Date: Sep 2016

Posts: 80

|

Donít put anything on wheel studs !

__________________

|

|

|

15 June 2018, 21:16

15 June 2018, 21:16

|

#3

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

I put a very light smear of copperslip on the studs. General wisdom is not to grease wheel studs, but generally wheel studs don't get repeatedly dunked in seawater.

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

15 June 2018, 21:36

15 June 2018, 21:36

|

#4

|

|

Member

Country: UK - England

Town: Portsmouth Area

Boat name: Busy Bee

Make: Ribcraft

Length: 5m +

Engine: Suzuki

Join Date: Jan 2012

Posts: 128

|

from a tire fitters website

There is a great deal of argument is whether to lubricate lug threads. Some swear by the use of some form of anti-seize on the threads, whether lithium grease, WD-40, motor oil or Teflon spray. The idea is to prevent rust and make it easier when it comes time to remove the lugs. Others recoil in horror, saying that lubing the threads will iresult in overtorqued nuts, or that the lubrication will cause the nuts to work themselves loose.

Manufacturers, engineers and other industry experts seem to unanimously oppose using lubrication. On the other hand, some customers, DIYers and self-appointed Internet forum experts claim to have used thread lube since the very dawn of time with nary a problem.

My own opinion is more nuanced. I disapprove of lubricating threads in general, unless they are badly rusted. Most lug bolts and lug studs are coated with a substance intended to prevent rust, but certain makes and models seem to be much more vulnerable to rust than others (Iím looking at you, Volvo).

In that case I can see applying a small amount of lubricant to prevent further corrosion, but only after carefully cleaning the rust off the threads with a wire brush. In most cases, however, I would simply ensure that the threads are clean and not bother with lubrication.

If you do apply lubricant, make sure to do so carefully and only to the threads. Never allow any lubricant on the mating surfaces of the nut or the lughole of the wheel.

Much of the ďstickinessĒ brought about by proper torque comes not from the threads but from the contact between mating surfaces. Even a thin film of oil between those surfaces can create a hydraulic barrier, preventing proper torque from being applied. This can also make it easier for the nut to work itself loose.

Either way, itís always best to get that customer to return in two weeks to check the lug nuts for tightness if any lubricants are used.

__________________

|

|

|

15 June 2018, 21:39

15 June 2018, 21:39

|

#5

|

|

Member

Country: UK - Scotland

Town: Fort William

Make: Ribcraft 585

Length: 5m +

Engine: Yamaha F115

Join Date: Mar 2012

Posts: 2,896

|

Quote:

Originally Posted by JimRib

Donít put anything on wheel studs !

|

Really?

Ive always put never seez on threads, not on the wheel/stud mating surface though.

__________________

There is a place on this planet for all of Gods creatures.........right next to my tatties and gravy.

|

|

|

15 June 2018, 21:49

15 June 2018, 21:49

|

#6

|

|

Member

Country: UK - England

Town: Wakefield

Boat name: Bouncer

Make: Redbay Stormforce

Length: 6m +

Engine: 2x Honda 100 Hp

MMSI: 235025718

Join Date: Jun 2009

Posts: 4,175

|

I can’t remember the last time I torqued any wheel nuts

Just swing on a bar till it’s FT

__________________

|

|

|

15 June 2018, 21:51

15 June 2018, 21:51

|

#7

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

I just use the windy gun

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

15 June 2018, 22:07

15 June 2018, 22:07

|

#8

|

|

Member

Country: UK - England

Town: Retford

Boat name: Spy-sea-one

Make: Excel 435

Length: 4m +

Engine: Suzuki Outboard/25/4

Join Date: Oct 2011

Posts: 7,454

|

Silicon grease lightly or PTFE spray check regular never had a problem or getting them off . I was told in Inverness even with dry nuts a wheel should be re-tightened after 200 hundred miles if it's been off OMO

__________________

|

|

|

15 June 2018, 22:14

15 June 2018, 22:14

|

#9

|

|

Member

Country: UK - Scotland

Town: denny

Boat name: breezy

Make: northcraft

Length: 6m +

Engine: honda 150

Join Date: May 2016

Posts: 888

|

copaslip for wheel nuts and bolts especially if its getting dipped in the sea anything is better than nothing I generally don't look at stuff until it falls to bits and ive never had any issues getting stuff apart

__________________

|

|

|

16 June 2018, 07:53

16 June 2018, 07:53

|

#10

|

|

Member

Country: UK - Scotland

Town: Aberdeenshire

Boat name: Sula

Make: Ribcraft 4.8m

Length: 4m +

Engine: Tohatsu 70hp + aux

MMSI: 235087213

Join Date: Jun 2007

Posts: 4,535

|

I've been using a slight smear of marine grease on my trailer wheel bolts and have done for years. Do the same on cars. Get yourself an extendable wheel ratchet (I carry one in all my cars) as the standard wheel brace is next to useless.

Remember a Volkswagen Polo my wife had years ago that the wheel lugs were absolutely seized. I applied pressure using a ratchet and extension bar and a little puff of rust and unmistakable crack and wheel bolt sheared. Lucking I managed to remove the remaining threaded stud as you can't drill hardened steel on the drive!

Good practice to check torque periodically.

__________________

Is that with or without VAT?

|

|

|

16 June 2018, 10:17

16 June 2018, 10:17

|

#11

|

|

Member

Country: UK - Scotland

Town: north ayrshire

Boat name: charlie girl

Make: S/R5.4/regal3760

Length: 10m +

Engine: Suzukidf70 2x6lp 315

Join Date: Jul 2009

Posts: 3,762

|

Quote:

Originally Posted by Pikey Dave

I put a very light smear of copperslip on the studs. General wisdom is not to grease wheel studs, but generally wheel studs don't get repeatedly dunked in seawater.

|

Copper grease is a nightmare if you ever overheat a brake drum due to the brakes sticking on, the copper dries out and seems to act as a solder and makes the bolts almost sieze.

I used to run a garage and routinely used to put a dab of copper grease on wheel bolts when servicing. But found if an owner roasted a brake for whatever reason it made the wheel bolts mega tight to get out

Same thing happens if you use it on manifold studs

Far better to use a graphite base like molyslip as40 or straightforward grease

For those that are concerned about wheel nuts falling off or being overtorqued due to lubrication locktite medium strength works well as an anti sieze as it stops corrosion of the threads

__________________

|

|

|

16 June 2018, 10:21

16 June 2018, 10:21

|

#12

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

Quote:

Originally Posted by beamishken

Copper grease is a nightmare if you ever overheat a brake drum due to the brakes sticking on, the copper dries out and seems to act as a solder and makes the bolts almost sieze.

I used to run a garage and routinely used to put a dab of copper grease on wheel bolts when servicing. But found if an owner roasted a brake for whatever reason it made the wheel bolts mega tight to get out

Same thing happens if you use it on manifold studs

Far better to use a graphite base like molyslip as40 or straightforward grease

|

I hear ya[emoji106] but mine are disc brakes[emoji16]

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

16 June 2018, 10:23

16 June 2018, 10:23

|

#13

|

|

Member

Country: UK - Scotland

Town: north ayrshire

Boat name: charlie girl

Make: S/R5.4/regal3760

Length: 10m +

Engine: Suzukidf70 2x6lp 315

Join Date: Jul 2009

Posts: 3,762

|

Quote:

Originally Posted by Pikey Dave

I hear ya[emoji106] but mine are disc brakes[emoji16]

|

Same applies if your pads sieze although i susspect you probably service more often than some of our customers used to so probably not a problem for yourself

__________________

|

|

|

16 June 2018, 14:06

16 June 2018, 14:06

|

#14

|

|

Member

Country: UK - Scotland

Make: HumberOceanOffshore

Length: 8m +

Engine: Volvo KAD300/DPX

Join Date: Oct 2002

Posts: 5,596

|

Quote:

Originally Posted by busybee

There is a great deal of argument is whether to lubricate lug threads. Some swear by the use of some form of anti-seize on the threads, whether lithium grease, WD-40, motor oil or Teflon spray. The idea is to prevent rust and make it easier when it comes time to remove the lugs. Others recoil in horror, saying that lubing the threads will iresult in overtorqued nuts, or that the lubrication will cause the nuts to work themselves loose.

Manufacturers, engineers and other industry experts seem to unanimously oppose using lubrication. On the other hand, some customers, DIYers and self-appointed Internet forum experts claim to have used thread lube since the very dawn of time with nary a problem.

My own opinion is more nuanced. I disapprove of lubricating threads in general, unless they are badly rusted. Most lug bolts and lug studs are coated with a substance intended to prevent rust, but certain makes and models seem to be much more vulnerable to rust than others (I’m looking at you, Volvo).

In that case I can see applying a small amount of lubricant to prevent further corrosion, but only after carefully cleaning the rust off the threads with a wire brush. In most cases, however, I would simply ensure that the threads are clean and not bother with lubrication.

If you do apply lubricant, make sure to do so carefully and only to the threads. Never allow any lubricant on the mating surfaces of the nut or the lughole of the wheel.

Much of the “stickiness” brought about by proper torque comes not from the threads but from the contact between mating surfaces. Even a thin film of oil between those surfaces can create a hydraulic barrier, preventing proper torque from being applied. This can also make it easier for the nut to work itself loose.

Either way, it’s always best to get that customer to return in two weeks to check the lug nuts for tightness if any lubricants are used.

|

I absolutely don't share that view, I pretty much always lubricate threads.

Dry threads may be fine if your device never sees water or salt or moisture or any other corrosive substance but my experience is that rarely is the case. The notion that a lubricated thread will come unscrewed more easily in the presence of a lubricant doesn't stand scrutiny.

To prevent corrosion the thread space needs to be filled with something to prevent ingress of the corrosive substance - by definition, tightening a threaded fastener will ensure a helical space down the unloaded side of the thread. If the corrosive agent is a liquid, which it commonly is, capillary action will ensure the space fills. Any light coating on a fastener will soon deteriorate and become worthless. Even well done chromium plating will break down in time. The only exception to this is where the fastener is a bolt fitted into a blind hole and the bolt head forms a permanent seal to the mating surface.

I'm not a lover of copaslip, dissimilar metals together in salt loaded water doesn't make sense to me.

With regard to wheel nuts, I use water resistant grease and if the stud protrudes through the nut I use a second greased nut to seal off the thread.

I'll climb down off me box now....

__________________

JW.

|

|

|

16 June 2018, 16:28

16 June 2018, 16:28

|

#15

|

|

Member

Country: UK - Scotland

Town: north ayrshire

Boat name: charlie girl

Make: S/R5.4/regal3760

Length: 10m +

Engine: Suzukidf70 2x6lp 315

Join Date: Jul 2009

Posts: 3,762

|

Quote:

Originally Posted by jwalker

I absolutely don't share that view, I pretty much always lubricate threads.

Dry threads may be fine if your device never sees water or salt or moisture or any other corrosive substance but my experience is that rarely is the case. The notion that a lubricated thread will come unscrewed more easily in the presence of a lubricant doesn't stand scrutiny.

To prevent corrosion the thread space needs to be filled with something to prevent ingress of the corrosive substance - by definition, tightening a threaded fastener will ensure a helical space down the unloaded side of the thread. If the corrosive agent is a liquid, which it commonly is, capillary action will ensure the space fills. Any light coating on a fastener will soon deteriorate and become worthless. Even well done chromium plating will break down in time. The only exception to this is where the fastener is a bolt fitted into a blind hole and the bolt head forms a permanent seal to the mating surface.

I'm not a lover of copaslip, dissimilar metals together in salt loaded water doesn't make sense to me.

With regard to wheel nuts, I use water resistant grease and if the stud protrudes through the nut I use a second greased nut to seal off the thread.

I'll climb down off me box now....  |

Pretty much my thoughts too

Dont know where the idea of using dry threads came from. Whenever you read torque instructions for a cylinder head (the most usual things I'd torque nowadays) it usually states lightly oiled threads and bottom surfaces of head bolts

__________________

|

|

|

16 June 2018, 16:39

16 June 2018, 16:39

|

#16

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

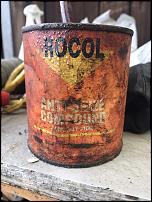

Here you go, the very stuff I use

And further reading

https://www.rocol.com/articles/anti-...duct-selection

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

16 June 2018, 20:08

16 June 2018, 20:08

|

#17

|

|

Member

Country: UK - Scotland

Town: north ayrshire

Boat name: charlie girl

Make: S/R5.4/regal3760

Length: 10m +

Engine: Suzukidf70 2x6lp 315

Join Date: Jul 2009

Posts: 3,762

|

Said on the tin when purchased in 1984 "use sparingly" 😉

__________________

|

|

|

16 June 2018, 21:50

16 June 2018, 21:50

|

#18

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

Quote:

Originally Posted by beamishken

Said on the tin when purchased in 1984 "use sparingly" [emoji6]

|

And I'm still only half way down the tin, that's the Yorkshireman [emoji6]

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

16 June 2018, 22:42

16 June 2018, 22:42

|

#19

|

|

Member

Country: UK - England

Town: South Yorks

Boat name: Black Pig

Make: Ribcraft

Length: 5m +

Engine: DF140a

MMSI: 235111389

Join Date: Feb 2008

Posts: 11,907

|

Quote:

Originally Posted by Pikey Dave

And I'm still only half way down the tin, that's the Yorkshireman [emoji6]

|

Ps, I've still got 2 unopened tins on the shelf, and some "nuclear grade"[emoji106]

__________________

Rule#2: Never argue with an idiot. He'll drag you down to his level & then beat you with experience.

Rule#3: Tha' can't educate pork.

Rule#4: Don't feed the troll

|

|

|

17 June 2018, 07:00

17 June 2018, 07:00

|

#20

|

|

Member

Country: UK - England

Town: Cheltenham

Make: Marex

Length: 9m +

Join Date: Oct 2011

Posts: 345

|

Hi Dave, i’m Beginning to wonder how big your shelf is as you seem to have one or more of everything on it!

Have a good Sunday

__________________

You Can't cross an Ocean unless you have lost site of shore.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

Recent Discussions

Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|